HVAC Controls in Alaska: Smarter Systems for Extreme Cold

- John Mortensen

- Nov 9, 2025

- 8 min read

HVAC Controls in Alaska: Smarter Systems for Extreme Cold

Alaska's commercial and public buildings face some of the most demanding environmental conditions on Earth. Long winters, extreme temperature swings, and remote logistics make heating, ventilation, and air conditioning (HVAC) performance critical for safety. Modern HVAC control systems, particularly Direct Digital Controls (DDC) have become essential to maintaining reliability, comfort, and energy efficiency across the state's diverse facilities.

From schools and hospitals to municipal buildings and research facilities, smart HVAC controls empower project managers, facility operators, and building owners to monitor, adjust, and optimize system performance from a computer screen in their office or remotely on a tablet or a mobile phone App. In Alaska, where every BTU and cost counts, these systems deliver measurable value.

Building Systems Vulnerable to Alaska's Cold

Commercial facilities in Alaska face unique cold-weather risks that demand intelligent HVAC control strategies for preventive design, real-time monitoring, and proactive maintenance. Advanced control systems play a critical role in maintaining operational continuity and preventing freeze-related damage across multiple building systems.

Plumbing and Water Systems

Domestic Water Piping: High risk in unheated service areas and ceiling plenums. HVAC control systems can maintain space temperatures above freezing through zone heating overrides and temperature monitoring alarms. Insulation, heat tracing, and continuous circulation loops should be tied into BAS alerts for flow verification.

Fire Sprinkler Systems: Dry and pre-action systems can freeze if compressors or drain heaters fail. Integration with the BAS allows monitoring of air pressure, ambient temperature, and supervisory alarms for faster response to freeze risk.

Sump and Drain Discharge Lines: Low-slope discharge lines can trap water and freeze, causing backups. Controls can monitor sump pump runtime, discharge temperature, and alarm if cycles deviate from programmed baselines.

Mechanical Equipment Connections: Cooling tower and humidifier supply lines should include seasonal lockouts within the BAS sequence to disable outdoor water feeds and enable 'winter mode' operation for protection.

Building Envelope, Materials, and Structure

Concrete and Masonry: Freeze–thaw cycles cause cracking and spalling in exposed foundations and parapets. Building automation can monitor exterior temperature trends and adjust adjacent heating zones or perimeter radiant loops to maintain thermal stability.

Roofing Assemblies: Ice dams and frozen roof drains often result from uncontrolled heat loss. HVAC controls integrated with snow and moisture sensors can regulate roof ventilation and heating to minimize ice formation.

Exterior Cladding and Glazing: Thermal expansion and condensation are influenced by interior humidity and temperature. Smart HVAC controls balance interior dew points and façade heating systems to reduce stress and moisture accumulation.

Loading Bays and Doors: Frequent door openings introduce large temperature swings. Control systems can activate air curtains, zone reheat coils, or vestibule heating automatically based on door position sensors.

Other Critical Systems

HVAC and Mechanical: Rooftop units, coils, and air handlers can freeze if freeze-stats, temperature sensors, or control sequences fail. BAS-integrated freeze protection monitors supply air temperature, valve position, and pump status, automatically opening valves or enabling circulation during extreme cold events.

Stored Liquids: Maintenance fluids and chemicals in mechanical rooms or service areas can freeze without adequate space conditioning. HVAC zone controls can maintain minimum setback temperatures and trigger alarms when ambient readings drop below thresholds.

Electrical Equipment: Condensation and freezing within outdoor panels or conduits can cause faults. Control systems can monitor enclosure temperatures and activate localized heaters under programmable logic to prevent icing.

Understanding HVAC Controls in the Alaskan Context

Safety is critical in commercial buildings in cold weather environments in Alaska to protect from anything to fire sprinkler lines to foundation drains.

At their core, HVAC controls regulate temperature, airflow, and indoor air quality by coordinating mechanical systems such as boilers, air handlers, pumps, and dampers. In Alaska, however, control systems must do far more, they must respond intelligently to extreme cold, fluctuating occupancy, and energy supply challenges.

A well‑designed control system ensures that facilities remain operational, comfortable, and energy‑efficient even in the harshest sub‑arctic conditions. Smart HVAC controls use sensors, automation sequences, and digital dashboards to manage heating and ventilation dynamically, conserving fuel while preventing freeze damage and ensuring code compliance.

Why HVAC Controls Matter More in Alaska

In most climates, HVAC systems are designed for comfort and efficiency. In Alaska, they're designed for survival especially in rural villages and small towns. Communities off of the road system with sea ice blockages of barges and shipping require all winter deliveries by air weather permitting. A failure in controls can freeze plumbing lines, compromise life‑safety systems, or shut down critical operations.

Controls technology helps overcome several Alaskan realities:

Extreme Climate and Seasonal Variation

Temperatures can swing 80°F or more between summer and winter. Automated control sequences adjust heating output, economizer operation, and ventilation rates to match real‑time conditions, reducing fuel waste and protecting mechanical systems from stress.

Limited Access and Remote Monitoring

In remote communities, sending technicians onsite for adjustments or troubleshooting can take days. DDC systems with cloud‑based access allow engineers and facility managers to monitor, diagnose, and fine‑tune systems remotely which is critical when an error message might otherwise lead to a costly shutdown.

Energy Efficiency and Fuel Management

Heating fuel and electricity are extremely expensive in rural Alaska. Smart controls coordinate equipment start‑ups, modulate valves and fans, and schedule setbacks to optimize performance during unoccupied hours. These energy management features can reduce operational costs by 15–30 %, freeing resources for other maintenance priorities.

Designing HVAC Controls for Alaska Buildings

Designing reliable and efficient HVAC control systems for commercial and public buildings in Alaska requires an integrated approach combining mechanical, electrical, and automation expertise. In sub-arctic climates, control systems must ensure continuous operation, freeze protection, and long-term energy performance.

Integrate HVAC controls with Building Automation Systems (BAS) for centralized monitoring, trending, and reporting.

Coordinate communication protocols (BACnet, Modbus, or LonWorks) for interoperability across mechanical and electrical systems.

Establish clear alarm hierarchies and remote notifications to alert operators to faults or freeze risks.

Use industrial-grade sensors and actuators rated for −40°F or below.

Protect outdoor sensors with heated, ventilated housings.

Include manual overrides for emergency operation during power loss.

Use dual temperature sensors and communication paths for redundancy.

Default control logic to safe heating modes during outages to prevent freeze damage.

Rotate equipment lead/lag sequences to balance runtime and ensure standby capacity.

Configure dashboards for outdoor temperature, efficiency, and alarm data.

Integrate metering to track energy use and detect inefficiencies.

Enable secure remote access for diagnostics and adjustments from remote locations.

Conduct factory acceptance tests (FATs) before delivery to remote sites.

Perform on-site functional testing in sub-freezing conditions.

Document sequences, setpoints, and as-built control logic for turnover.

Provide hands-on and digital training resources for operators.

Schedule remote seasonal recalibration sessions.

Protect BAS networks with firewalls, encryption, and role-based access.

Keep firmware updated and segregate BAS networks from public Wi-Fi.

Successful Control System Design Holistic Approach

Successful control system design in Alaska requires a holistic approach—integrating mechanical, electrical, and building envelope considerations. Coordination across CSI Divisions 23 (HVAC) and 26 (Electrical) ensures that every component functions reliably under extreme conditions.

Robust Sensors and Field Devices

Temperature, humidity, and pressure sensors must be rated for sub‑zero operation. Outdoor sensors need protective housings and heated elements to prevent frost buildup and inaccurate readings. Field devices like actuators and valves should include manual overrides for emergency operation if control power is lost.

Redundant and Fail‑Safe Programming

HVAC controls in Alaska often include built‑in redundancy—such as dual temperature sensors or backup communication networks—to maintain operation if one component fails. Programming logic must default to safe positions, ensuring continuous heating or freeze protection during outages.

Integration With Building Automation Systems

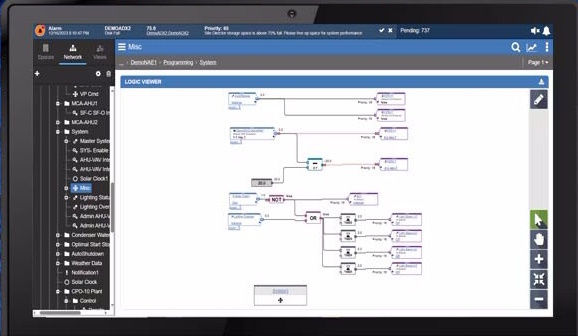

Modern DDC platforms connect HVAC controls with Building Automation Systems (BAS) which include lighting, electrical metering, and security systems. This integration enables coordinated energy management and simplifies facility oversight, especially for public agencies operating multiple remote sites.

Integrated Building Automation Systems (BAS)

Building Automation Systems integrate mechanical, electrical, and safety systems for unified facility management.

HVAC Management: Controls air handling, humidity, and ventilation across zones.

Lighting Control: Adjusts based on occupancy and daylight.

Security and Access: Integrates card readers, cameras, and alarms.

Fire and Life Safety: Coordinates smoke control and egress during emergencies.

Energy Management: Monitors energy consumption and identifies inefficiencies.

Plumbing and Leak Detection: Monitors water flow and can automatically close valves.

Electrical System Oversight: Tracks switchgear, loads, and power quality.

Project Management and Commissioning Best Practices

For owners and project managers, HVAC controls demand rigorous oversight from design through commissioning. In Alaska, success depends on attention to detail, documentation, and testing, especially when schedules are tight and mobilizations are limited.

Early Coordination and Clear Specifications

Controls scope should be clearly defined with the design team and engineers in the design phase. Coordination between the mechanical engineer, electrical designer, and controls contractor is critical to prevent gaps in wiring, sequence logic, or integration responsibilities. Using standardized specifications and CSI divisions ensures consistency across bids and submittals.

Factory and Field Testing

Before systems are shipped or energized, all control panels and programs should be bench‑tested. Once onsite, field verification confirms sensor calibration, sequence accuracy, and communication with the building automation system. In Alaska, where return trips are expensive, one thorough commissioning visit saves many headaches.

Training and Long‑Term Support

Operator training is essential. Facilities personnel must understand system dashboards, alarm protocols, and manual overrides. For remote sites, documentation and digital training resources ensure staff can troubleshoot issues between maintenance visits.

Smart Controls in Action: Alaska‑Style Performance

Consider a mid‑size municipal office building in Western Alaska. The facility uses a fuel‑oil boiler plant with variable‑air‑volume air handlers. Smart controls monitor indoor temperatures, outdoor conditions, and equipment efficiency in real time. When temperatures drop below −20°F, the system automatically increases circulation and activates heat recovery ventilators. During mild shoulder seasons, economizers introduce fresh air to reduce heating demand.

Through automated scheduling and optimization, the building reduces fuel consumption by 25%, improves occupant comfort, and provides continuous data to the facility management team hundreds of miles away. This is a tangible advantage of well‑implemented HVAC controls.

Smart HVAC Controls: Key Features for Commercial Buildings

Intelligent Scheduling: Adjusts system operation based on occupancy and time of day.

Remote Access: Facility managers can monitor and modify systems from anywhere.

Environmental Sensors: Measure temperature, humidity, and occupancy to balance comfort and efficiency.

Automated Freeze Protection: Sequences adjust to outdoor temperature and humidity to prevent coil freezing.

Air Quality Management: Tracks CO₂ and humidity for healthier work environments.

Zoned Control: Delivers precise temperature management across multiple zones.

Benefits of Smart HVAC Systems in Commercial Facilities

Operational Efficiency: Optimized control reduces fuel and electricity costs by 15–30%.

Asset Protection: Continuous monitoring prevents coil and pipe freeze damage.

Enhanced Comfort: Ensures consistent temperature and air quality for occupants.

Reduced Downtime: Predictive maintenance reduces emergency calls.

Sustainability: Supports LEED and ASHRAE 90.1 compliance through improved energy management.

The Future of HVAC Controls in Alaska

Technology continues to advance rapidly. Wireless sensors, AI‑driven fault detection, and cloud‑based analytics are making control systems smarter and more proactive. For Alaska, these innovations mean fewer site visits, lower operating costs, and faster response to maintenance issues. As renewable energy integration expands, HVAC controls will also coordinate between solar, wind, and conventional fuel systems to maintain balance and efficiency across the grid.

Conclusion: Building Reliability Through Smart Controls

In Alaska's extreme environment, HVAC control systems are more than a convenience—they're a lifeline. They protect infrastructure, conserve fuel, and enhance comfort while supporting long‑term sustainability goals.

Smart controls combine technology, engineering, and disciplined project management to keep facilities operating safely and efficiently year‑round. For public agencies, schools, and commercial property owners, investing in well‑designed HVAC controls isn't just good practice; it's essential for resilience in the Last Frontier.

To learn how structured project management and smart building systems can improve your next project, visit Fremontii's Service's page or go to Fremontii's Contact Page to start a discussion for your facility needs.